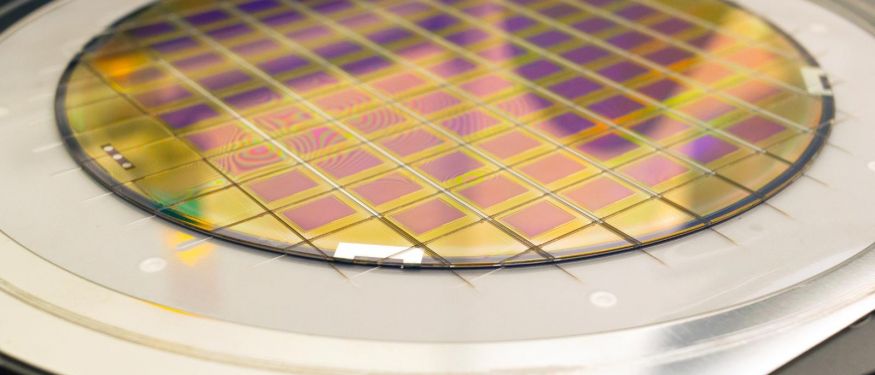

People who genuinely want to understand technology should take time to understand what wafers are. These silicon discs are the substrate for a vast number of chips with circuitry embedded into them or even written onto the chips themselves. These circles with chips cut into them can make for a vivid sight.

But what other technology is used in wafer fabrication? One key piece of technology that’s often overlooked: the wafer chuck. This simple device plays a surprisingly pivotal role.

Wafer Chucks

What is a wafer chuck? Or for that matter, what is chucking? A wafer chuck is a metal plate used to hold a silicon wafer in place during testing. These metal plates use a slight amount of pressure to accomplish this task

Wafer chucking plates are unique because of the elements of their design. A wafer chuck is almost always round, though variants for testing substrates for hard disk drives or optical window displays require square or rectangular chucks, and just slightly larger than the largest wafer it is designed to hold. These plates range in size from 50mm to just over 300mm, matching the sizes of the most common wafers on the market. They’re ideal matches for the wafers.

What Are Wafer Chucks Made From?

Wafer chucks boast a more diverse material base than the wafers they hold. The devices are most often made from aluminum, prized for their low cost and superior thermal conductivity. However as different tests have different needs, other materials such as brass, bronze, ceramics, or glass are popular for wafer chucks. Furthermore, the devices have some insulating coatings applied, such as zinc or nickel plating.

How Do Wafer Chucks Work?

Wafer chucks have a very distinctive design that comes from their use. The devices have a series of locking rings used to hold different sizes of wafers in place. These range greatly, allowing you to use a single wafer chuck for multiple sizes, eliminating the need to own multiple wafer chucks. This simple step also allows you to work on both whole and partial wafers, making it particularly useful when testing only one part of a whole.

Generally, the chucks have either vacuum grooves or patterns of micro holes stamped into the devices. The grooves or holes tightly hold the wafer into place. Furthermore, lift pins in the devices automatically lift and raise the plates as needed during the testing process.

What Wafer Chuck Works Best For You?

While wafer chucks can adjust for size, it’s important to know which wafer chucks will most precisely fit your needs. Examine the coating on the chuck to ensure proper adhesion. Check that the material the wafer chuck is made from will stand up to your testing needs. Finally, if you are working on a specialized substrate, be sure to have the right chuck.

A wafer chuck is an essential component of testing silicon wafers. Silyb Wafer Services aims to provide you with the finest products for test wafers on the market. Visit our site to explore all we have to offer.

Published June 22, 2023.